Spoiler Alert: There is no Santa.

But there is a workshop where many hands, attached to regular size people, build beautiful toys for boys and girls around the world. From design, to component sourcing, to building and delivery, every Mission bicycle takes a whole team to execute. It's not magic, it's hard work and the abridged version goes something like this:

Compose

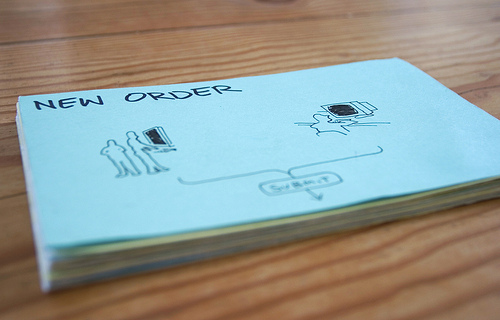

A new bike design comes in. Our Front of House staff starts the process by confirming all specs and capturing all of the customers intentions. In addition to the obvious stuff, like gearing and color, there are subtleties like cable housing color and brake lever placement. Once confirmed, a physical build sheet is written up that will follow the order through to completion.

Our manager Jefferson hand drew these cards, and the other 17 not pictured, as a training tool for new staffers.

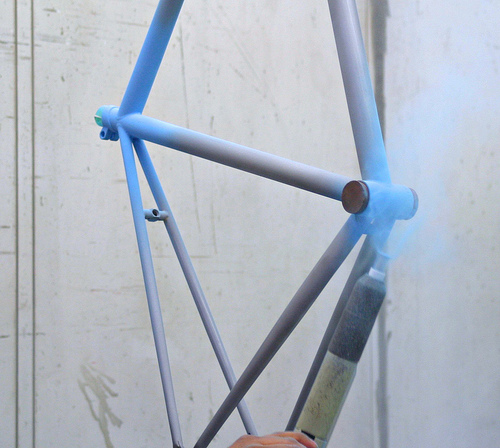

Paint

Our frames are painted, more accurately powder coated, one at a time in South San Francisco. Each one is coated in an electro-static powder, one of hundreds of colors, before being cured in a giant walk-in oven. About a week later we get frames back in beautiful and durable finishes.

A Valencia frame being powder coated Sky Blue.

Collect

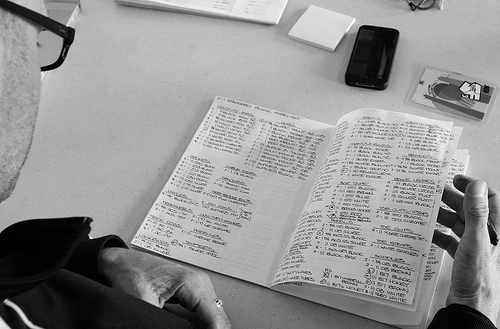

Meanwhile our mechanic and brand manager Brian will use the build sheet to order each and every part. Ordering for each bike allows complete customization, rather than limiting riders to fewer in-house options. Once the components arrive, they are collected into a build box to await fabrication.

Brian compiling parts for this week's order.

Wild Card

What happens if a rider changes his/her mind half way through the process and wants a black stem angled up, instead of a silver stem angled down? Then we make that change by sourcing a new part or borrowing one from a later build. Changes are common, often involve 3 to 4 staffers, and are a natural part of the design process.

Fabricate

The process then moves to our mechanics in Back of House. They start by hand-building wheels. One rim, three dozen spokes, three dozen nipples and about an hour of concentration yields one wheel. They repeat the process for each bike and hang the wheels in waiting.

Once the frame is back from the painter, the build box is complete, and the order is next in line, the bike gets built. Our team of handsome and skilled mechanics will pull the frame off the wall, study the build sheet and then set to work.

Depending on the design and complexity it takes anywhere from 2 to 4 hours to build a Mission bicycle. Once finished, the bike and the well worn build sheet head back to Front of House for the final leg.

James installing brake cable and housing.

Release

The last step is bittersweet. The bike is handed off to its anxious owner and released into the wild. Where our job ends, yours begins. Go ride.

Cody on pick-up day with his new goldenrod Valencia.